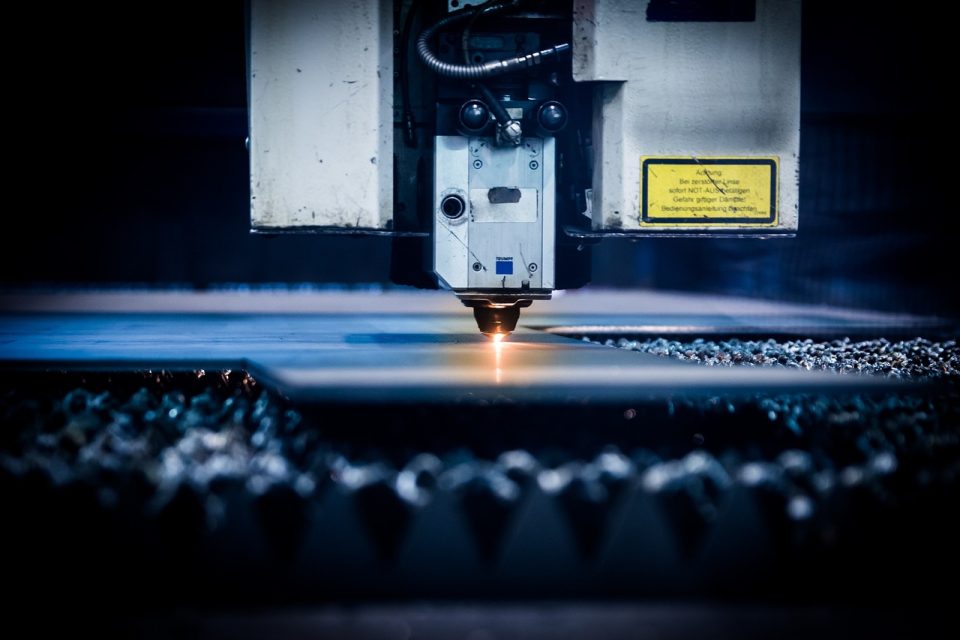

Modern laser cutting gaskets technology has emerged as the superior solution for applications demanding exact specifications and complex geometries. The manufacturing industry has witnessed a remarkable transformation in how sealing solutions are created. Traditional die-cutting methods, while effective for large-scale production, often fall short when precision and customization are paramount. Modern laser cutting gaskets technology has emerged as the superior solution for applications demanding exact specifications and complex geometries.

This advanced manufacturing process utilizes concentrated light beams to cut through various materials with unprecedented accuracy. The technology achieves tolerances as tight as ±0.001 inches, making it ideal for critical sealing applications in aerospace, medical devices, and semiconductor manufacturing.

Understanding the Laser Cutting Process

The process begins with computer-aided design (CAD) files that define the exact gasket dimensions. These digital blueprints are translated into precise cutting paths that the laser follows. Unlike mechanical cutting methods, the laser beam creates clean edges without physical contact, eliminating the risk of material deformation or contamination.

The non-contact nature of this process is particularly beneficial when working with delicate materials like PTFE gaskets. These fluoropolymer seals require careful handling to maintain their chemical resistance and temperature stability properties. The laser’s focused energy creates smooth, burr-free edges that enhance sealing performance.

Material Versatility and Applications

Modern laser systems can process an extensive range of gasket materials, from soft elastomers to rigid plastics. Each material responds differently to laser energy, requiring specific power settings and cutting speeds. Rubber compounds, silicone sheets, and compressed fiber materials all benefit from the precision this technology offers.

PTFE gaskets represent one of the most challenging yet rewarding applications. Their exceptional chemical inertness and wide temperature range make them indispensable in chemical processing and pharmaceutical industries. The laser’s ability to create intricate patterns and tight radii in these materials opens new possibilities for complex sealing designs.

Advantages Over Traditional Cutting Methods

The superiority of laser cutting gaskets becomes evident when comparing production flexibility and quality outcomes. Traditional die-cutting requires expensive tooling for each design variation, making small batches economically unfeasible. Laser systems eliminate tooling costs entirely, allowing manufacturers to produce custom gaskets on demand.

Quality improvements extend beyond dimensional accuracy. The heat-affected zone in laser cutting is minimal, preserving the material properties crucial for sealing performance. This is especially important for engineered materials where thermal degradation could compromise chemical resistance or mechanical strength.

Economic Benefits and Production Efficiency

The economic advantages extend throughout the production cycle. Setup times are dramatically reduced since no physical tooling changes are required between different gasket designs. A manufacturer can switch from producing standard ring gaskets to complex multi-port designs in minutes rather than hours.

Waste reduction represents another significant cost saving. The precision of laser cutting gaskets minimizes material usage, with nesting software optimizing sheet utilization. This efficiency is particularly valuable when working with expensive materials like specialized PTFE gaskets or high-performance elastomers.

Quality Control and Consistency

Advanced laser systems incorporate real-time monitoring capabilities that ensure consistent quality across production runs. Sensors track cutting parameters, automatically adjusting power and speed to maintain optimal results. This level of control is impossible with mechanical cutting methods where tool wear gradually affects cut quality.

The digital nature of the process also enables comprehensive documentation. Every gasket produced can be traced to specific production parameters, supporting quality management systems in regulated industries. This traceability is essential for critical applications where gasket failure could have severe consequences.

Future Developments and Industry Trends

The technology continues to evolve with improvements in laser power sources and control systems. Newer fiber laser systems offer even greater precision while reducing operating costs. Integration with automated material handling systems is creating fully autonomous production cells capable of 24/7 operation.

Artificial intelligence is beginning to optimize cutting parameters automatically, analyzing material properties in real-time to achieve perfect cuts. These developments promise to make laser cutting gaskets even more accessible to manufacturers seeking superior sealing solutions.

The combination of precision, flexibility, and efficiency positions this technology as the definitive solution for modern gasket manufacturing. As industries demand tighter tolerances and more complex designs, laser cutting provides the capabilities needed to meet these challenges while maintaining economic viability.